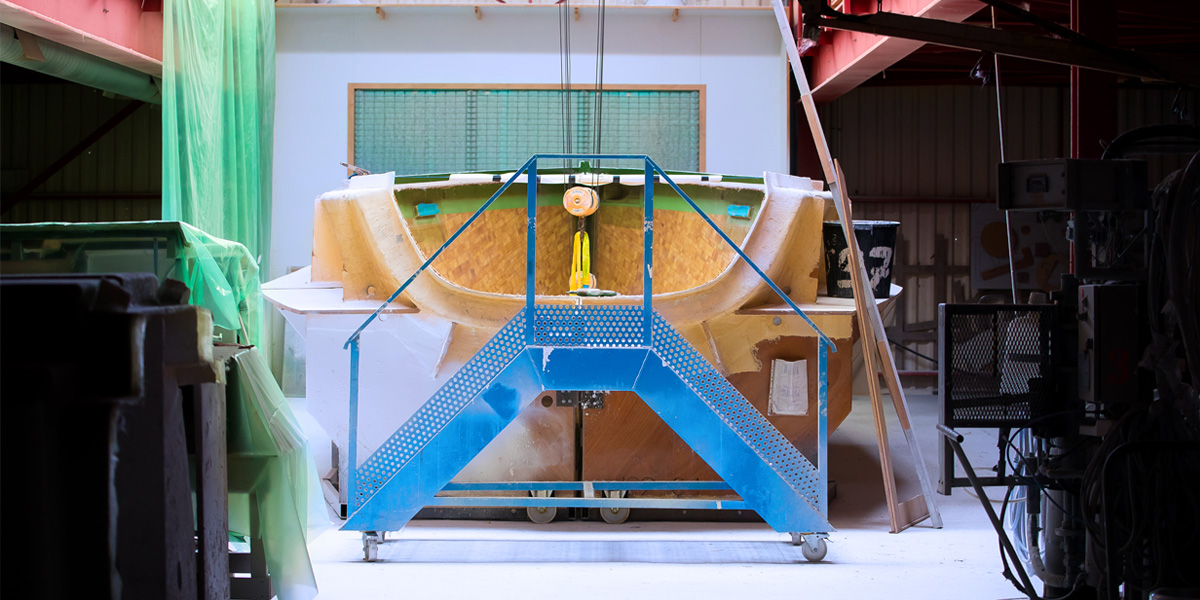

Manufacturing know-how

Sandwich and infusion construction is one of the most technological and specialised processes on the market

We boast 30 years of experience since filing the Scrimp patent

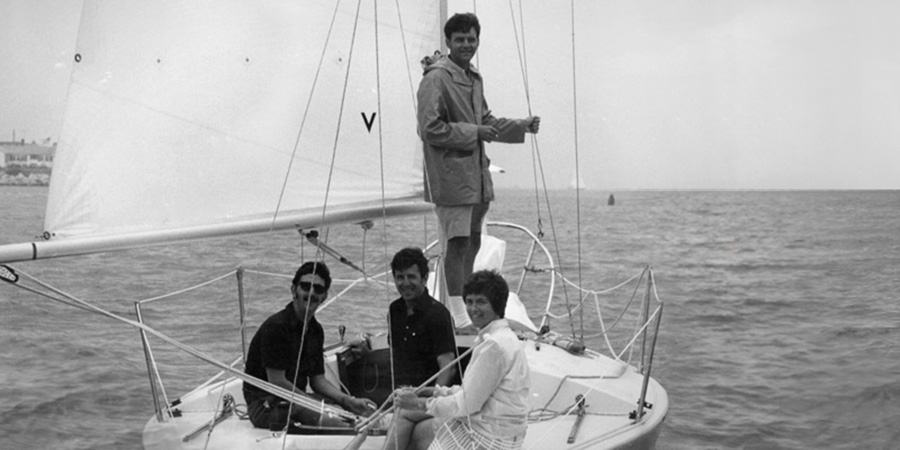

Creation of J Boats with the launch of the J/24

Assembly of the first J/92 by the French team

Assembly of the first J/110 J/120 (respectively the predecessor of the J/112 E and the J/122 E) in France with accommodation adapted to the European market

Launch of the J/109 (predecessor of the J/112 E), the first of the J Boats developed jointly by the French team to be tailored as best as possible to the European market

J is accessible to all today. Because J Composites wants sailing enthusiasts everywhere to head out to sea, not just athletes.

I met Jeff Johnstone during the World Sailing Games in La Rochelle in July 1994. We very quickly got along and I created J Composites in December of the same year. At the time, we were the builder of Js under licence with the Americans from J Boats. We began with the design of the J/92 then the J/80. Today, we are still under licence albeit with wider scope, since in addition to manufacturing Js, we market them and we’re developing the ranges.

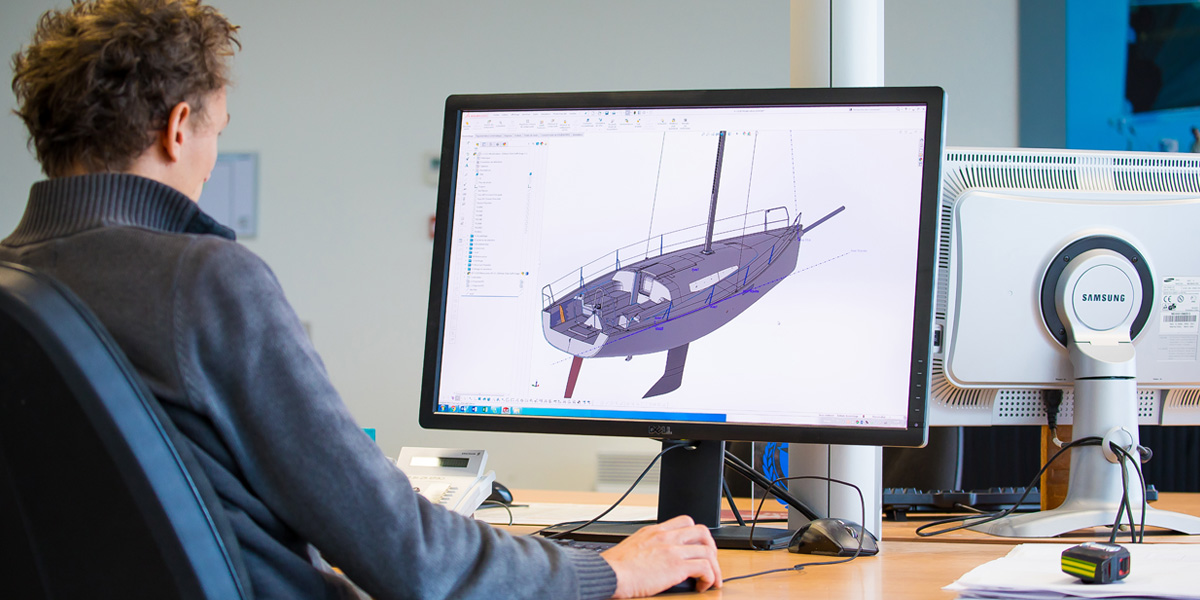

We are a yard in our own right, which works from the designs of the Johnstone family, but we take the process a lot further than that since we are incredibly proactive with regards the launch of each and every product. We have extensive knowledge of the market together with considerable expertise. The Elegance range is the fruit of an idea by J Composites for example.

Sandwich and infusion construction is one of the most technological and specialised processes on the market

We boast 30 years of experience since filing the Scrimp patent

Nothing beats a factory visit to assess why a J is unique.

As such we invite all our clients to come and visit the yard as well as monitor production of their boat

The standard version offers an unrivalled standard of equipment. The standard spinnaker hardware on a retractable carbon bowsprit is just such an example. The finish of the hull and the appendages is also unequalled on this market

In essence, a J boat is about drawing up specifications linked to performance and how easy she is to sail. Next, we develop the interior by optimising the spaces as best we can.

We continue to believe that the primary asset of a sailboat is the pleasure you get from sailing her

The integrated design office enables us to constantly optimise the parts we assemble in relation to the evolution of the market. We can also offer a unique series of optimisations for the grand prix division through the creation of custom parts